Anodizing is an electrochemical process that forms a durable oxide coating on aluminum. The anodic coating is part of the metal but has a porous structure that allows secondary infusion, such as coloring.

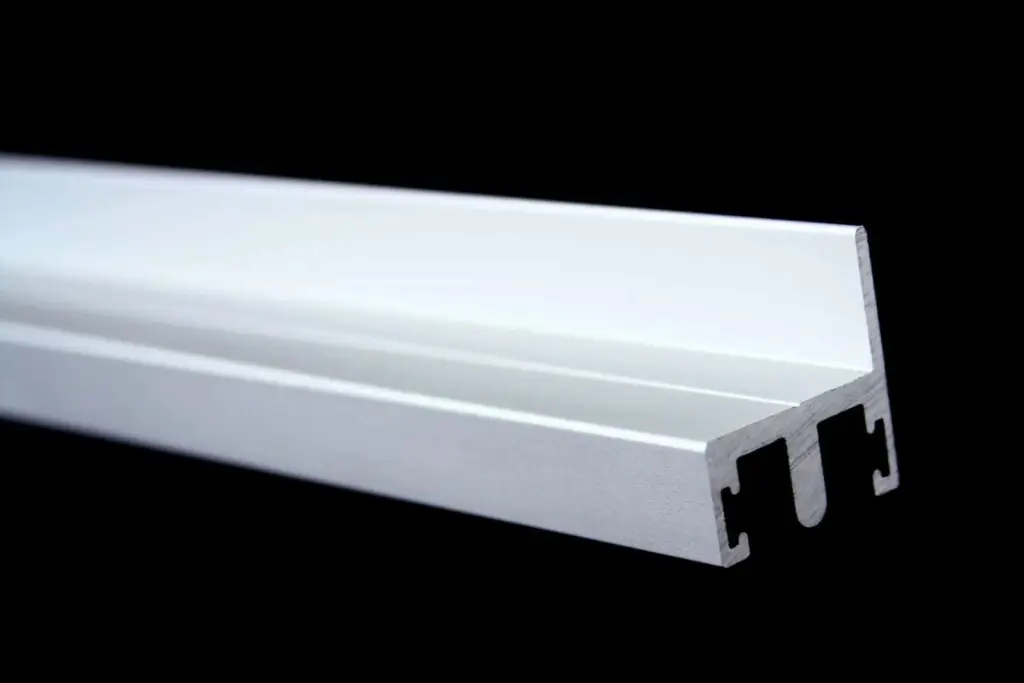

200 R5

Silver

Mechanically Buffed, Brushed, or Mill Brite

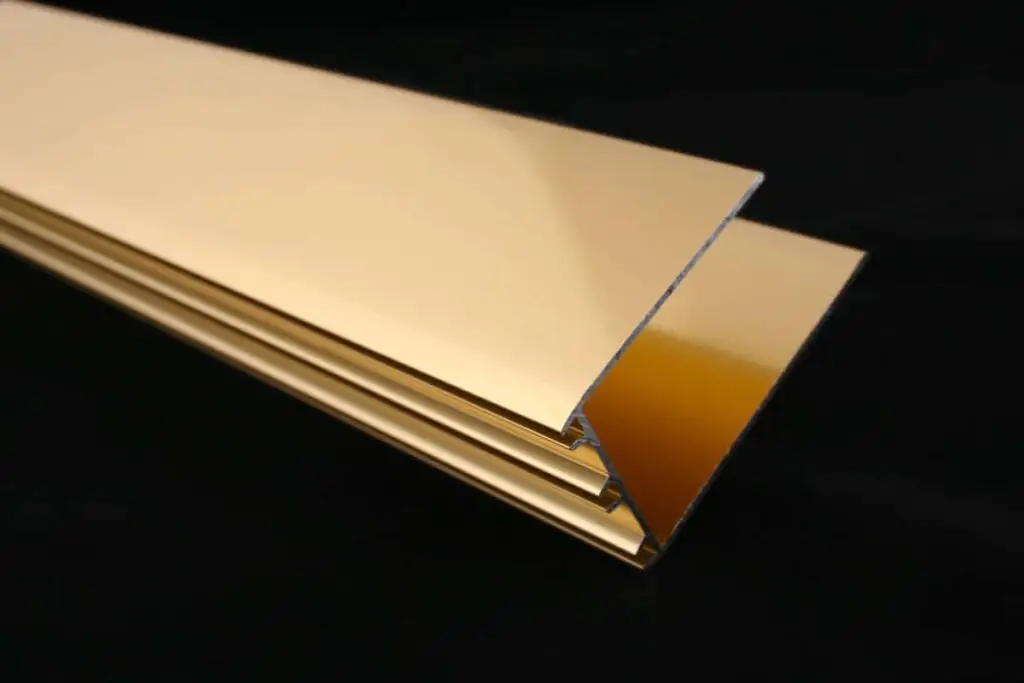

203 R5

Gold

Mechanically Buffed, Brushed, or Mill Brite

215 R5

Black

Mechanically Buffed, Brushed, or Mill Brite

214 R5

Nickel

Mechanically Brushed

200 R1

Silver Matte Finish

Environmentally Friendly

203 R1

Gold Matte Finish

Environmentally Friendly

215 R1

Black Matte Finish

Environmentally Friendly

Anodizing Tank Size and Finishes

Brite Dip finishes:

Acid Etch Finishes:

Briteline has many racking options. It is important to discuss your precise requirements for “good metal” and rack mark areas with your Briteline Sales Representative.

Contact Our Team

Phone: (843) 873-4410

Fax: (843) 873-8129

"*" indicates required fields