Our Capabilities

Briteline Extrusions is designed to be your one stop source for high-quality extruded, fabricated and finished aluminum parts produced entirely at our plant in Summerville, SC.

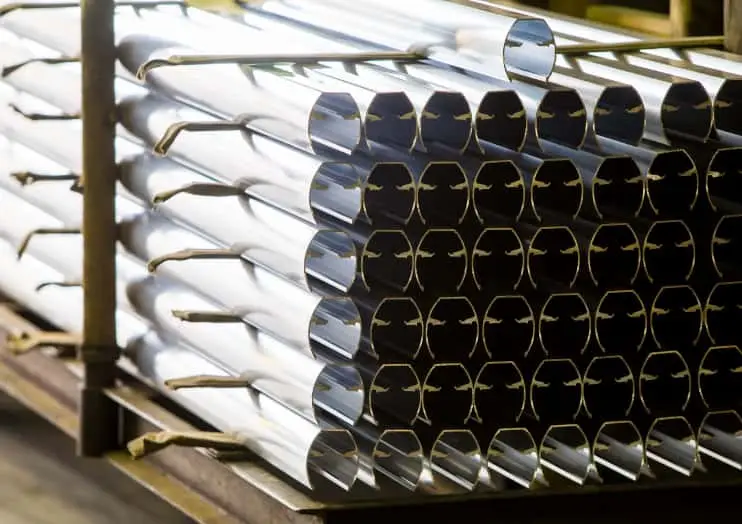

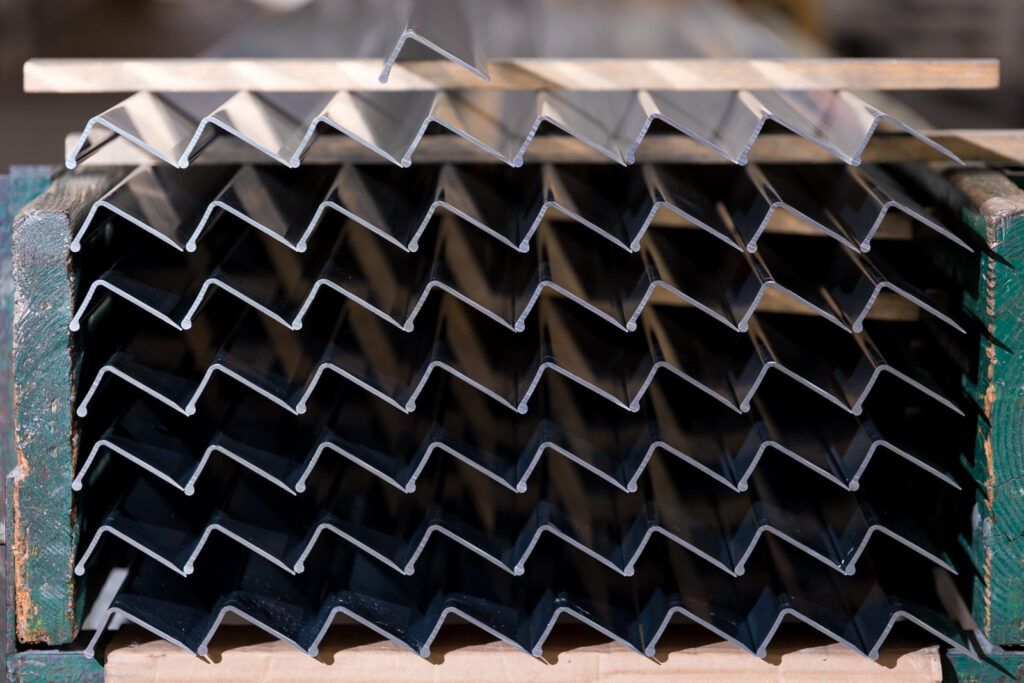

Presses

Our 6-inch extrusion presses are designed to extrude small, lightweight shapes. We can extrude solids or hollows that fit inside the 6” circle size.

Billet/Alloy

We use primary and secondary billet from the aluminum industry’s top suppliers.

6063 Alloy

The most popular extrusion alloy. Good surface finish; good corrosion-resistance; good machinability. Heat treatable.

6463 Alloy

Designed to accept a bright finish through anodizing and/or polishing. Good surface finish; good corrosion-resistance; good machinability. Heat treatable.

Temper

T5

Extrusions are cooled from an elevated temperature and artificially aged. Webster reading 10-12

T42

No artificial aging. Material will be soft. Webster reading 2-3. Will naturally age over time and become hard.

Stabilize

Heat treat at 365 degrees for three hours. Metal will be bendable, but will not harden any further over time. Webster reading 7-8.

Finishing

Brite Dip Anodizing

Silver, Black, Gold, Nickel. Maximum Length: 16’

Mill Brite Anodizing

Silver, Black, Gold, Nickel. Maximum Length: 16’

Acid Etch Anodizing

Silver, Black, Gold, Nickel. Maximum Length: Solids: 20’ Hollows 18’

Mechanical Finishing

Buff Maximum Length: 20’ Brush Maximum Length: 14’

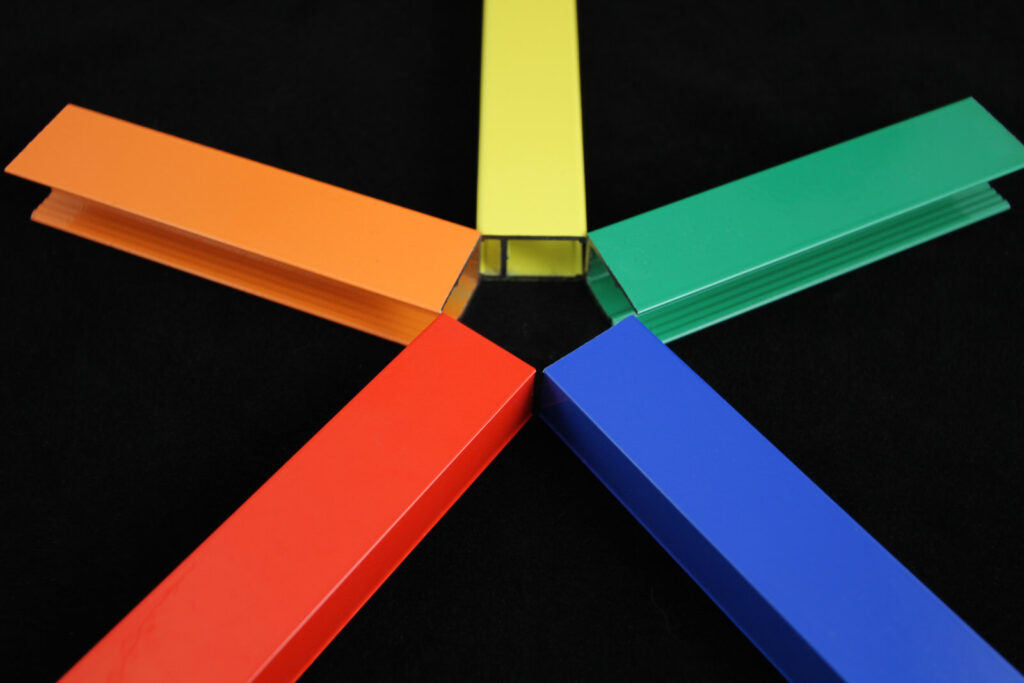

Powder Coat

14’ Maximum length. Stock color and custom color options.

Briteline Production, Design Services

- AutoCAD Design Assistance

- Die Shop on site

- Extensive selection of standard dies

- Fabrication expertise